More than 100 billion tons of resources enter the economy every year – everything from metals, minerals, and fossil fuels to organic materials from plants and animals. The use of these resources has tripled since 1970, and could double again by 2050 if business continues as usual.

However, less than 9% of all resources are recycled and used again.

This unsustainable rate of consumption has devastating effects for humans, wildlife, and the planet. In fact, we would need 1.5 Earths to support our current rate of consumption.

Removing Waste from the Model

It is more urgent than ever to shift from a linear, use-it-up-and-throw-it-away model to a circular economy – where waste and pollution are designed out, products and materials are kept in use longer, and natural systems can regenerate.

The Ellen McArthur Foundation describes the circular economy as “gradually decoupling economic activity from the consumption of finite resources and designing waste out of the system”.

Knowing that we only have one earth, which does not have a limitless supply of materials, has increasingly given the circular economy a proper stage. Every year, more businesses embrace this platform and transition to a circular economy system of production to become more sustainable – and reduce long-term operating costs.

At the end of the day – wasting less means spending less.

In a report entitled Waste to Wealth, Accenture estimated that moving to a circular economic model could add $4.5 trillion in economic output by 2030. This is between 4-5% of the projected global gross domestic product (GDP).

Closing the Supply Chain Loop

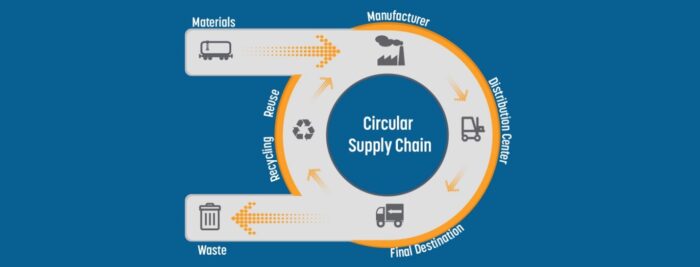

In the past, supply chains were built in a linear fashion. They started with suppliers shipping raw materials to a manufacturing facility, which in turn shipped finished goods further down the supply chain to a distribution center to be delivered to end customers. The workflow was point-to-point, and end-products typically ended in the trash after use.

Today’s supply chains are becoming circular by adding a link to connect the beginning and end of the chain to create a closed-loop system. This link encompasses returns and recycling, taking waste materials and returned goods and turning them into products which can be resold.

The “make-use-return” philosophy on which circularity is based may seem straightforward, but the logistics are far from simple. Used product or components come in countless forms and must be moved between various nodes, including pick-up and storage points, recycling or refurbishment centers, and manufacturing plants. Many times, the product flows between these nodes need to support just-in-time production schedules.

Reclaiming components and materials from end-of-life products to make new products is not the same as procuring virgin materials and new components for manufacturing operations. Supply is subject to the availability of materials from waste streams, which can be variable. In consumer electronics, for example, the supply of materials for reuse fluctuates with the amount of end-of-life product discarded by users.

Establishing efficient return channels for used product is a significant challenge, especially in consumer markets. Some companies are exploring the use of e-commerce returns services as convenient channels for collecting end-of-life product.

Moving circular supply chains into the mainstream requires combining the expertise gained in the linear world with new thinking in supply chain management.

Moving to Product-as-a-Service

A circular economy also requires enterprises to rethink their business model to not only build value into producing and commissioning products, but also in decommissioning and recycling the products. A business can no longer be based solely on one-directional logistics and value chains.

Traditionally, a product’s value increases during manufacturing and shipping processes, in the early stage of the product’s life cycle. The value decreases during the operation phase, and might be zero or even negative (waste) when product is decommissioned after it has reached the maximum operation time. Many companies have built their business models based on maximal efficiency in this one-way value stream.

To participate in a circular economy, businesses must evaluate alternative revenue streams besides producing new products, including revenue generated from the embedded value in products. A circular business model is sustainable only if embedded value can be economically recovered from the product. It might be realized through reusing the product – which extends the value of the materials and energy invested in the manufacturing process – or by dismantling it into components or raw materials to be recycled for some other use.

Embedded value will be offset by the cost of returns and recycling, which can vary depending on product type. Returning a washing machine, for example, will clearly be much harder and more expensive than an ink cartridge.

To increase recovered value, manufacturers are investing in processes to extend the life of their products, by making them easier to disassemble for repairs through modularity. They are also offering end-customers incentives to return their used products instead of throwing them away.

Redesigning a product to have extended life enables manufacturers to realize more revenue from offering their product as a service, rather than from selling the product. To that end, the service economy is having a positive impact on the circular economy. Offering a product as a service is a shift away from the ‘buy and waste’ approach.

If a washing machine is sold based on a subscription contract, there is little incentive for the manufacturer to make it obsolete and a large incentive to reuse as many parts as possible.

Philips, for example, has generated significant business value by embracing the Product-as-a-Service model. Its Lumify offering is a subscription service that provides customers with access to ultrasound transducers, apps, and an online ecosystem.

Another example is Xerox. Its pay-per-use model both discourages frivolous usage, prolonging the life of the machine, and allows Xerox to retain ownership of its products. The modular design of its copiers’ inner workings, most of which are standardized for all models, also extends useful life. Across product generations, Xerox recycles, reuses, and refurbishes standard components while changing the core imaging technology— keeping machines in action longer.

The company complements these approaches with an ambitious material-recycling program. It claims to be reducing its virgin-resource inputs by hundreds of tons a year, and the internal components of its machines are made from 100% recycled plastics.

Driving Initiatives and Innovation

While electronics offerings like these have high embedded value, the cost of returns and recycling can also by high. Collaborative initiatives and innovative approaches are required to reduce these costs and incentivize end-of-life returns of electronics – which have already become the world’s fastest-growing waste stream, with less than 20% of global e-waste being formally collected and recycled.

Each year, more than 1.5 billion mobile phones are manufactured worldwide yet just 1-2% of these phones are recycled globally.

To help drive the circular economy for electronics, the “Re” initiative of Orange telecom has ramped up the collection rate (recycling + returns) of used mobile equipment in France, from 13.4% in 2020 to 22.3% in 2021, in line with the 30% target Orange has set for 2025. In total, around 1.9 million units have been returned and recycled since the initiative launched. Based on these impressive results, Orange is now extending this initiative throughout Europe.

Innovative and automated systems that combine hardware and software can speed up the rate of device grading and improve cost effectiveness and accuracy. These systems can perform highly accurate and fast cosmetic grading on returned and refurbished equipment.

Ingram Micro’s REV, for example, is a fully automated device processing machine that conducts over 100 functional tests simultaneously and uses sound and light tests to provide a dramatically more accurate cosmetic grade. Each REV system can process 2 million devices annually.

Ingram Micro has partnered with O2, the principal brand of Telefónica UK, to help recycle over 450,000 devices or 75 metric tons of e-waste to date. Of the devices that were recycled, over 40% were refurbished, cleared of data, and sold back to networks for new customers to use.

Looking to CloudBlue and Ingram Micro

With over 39,000 associates and thousands of suppliers, Ingram Micro recognizes the impact of its global operations on ecological systems and is dedicated to environmental stewardship.

From increasing renewable energy use, to streamlining transportation and packaging processes, to working with customers to reduce e-waste and support circular economy strategies, Ingram Micro is committed to implementing environmentally responsible practices.

As an Ingram Micro subsidiary and member of the Digital Twin Consortium and TM Forum, CloudBlue collaborates with global technology partners to accelerate innovation that drives sustainability. Its mission is to fundamentally reshape how businesses offer value to customers through a global delivery system of Everything-as-a-Service that supports the Product-as-a-Service business model.

Future-focused companies know that value exists in the circular economy and are moving toward sustainable processes and products. As ecosystem enablers, CloudBlue and Ingram Micro are committed to do all we can to empower our technology partners to thrive in this circular economy. We can all make a world of difference. New models will help us do it together.